- OUR APPROACH

-

COMMITTED TO YOUR SUCCESS

Our approach, developed over decades of experience, is fine-tuned to get the results you want.

We deliver concept-to-completion solutions, designed by temporary power specialists with access to the largest inventory of high-quality power generation and distribution equipment in North America.

-

- Equipment

-

RENTALS

From a wide range of diesel and natural gas generators to transformers, cable, light towers and more, our large rental fleet and extensive vendor network ensure we’ll have the temporary power equipment that your project requires — every time.

-

- Industries

-

INDUSTRIES WE SERVE

For nearly 20 years, we have been at work powering projects across Canada’s industrial sectors.

Select from this sampling of industries to learn how we can put our expertise to work for you.

VIEW ALL- Projects

- About

-

A PROUD HISTORY. A BRIGHT FUTURE.

From our inception in 1998, we have been building our team on a foundation of excellence. Our team members’ passion, expertise and commitment are what have allowed us to grow into a national company with projects across Canada.

Click on the links to learn more about our history, our team or our career opportunities.

- Blog

- Contact

-

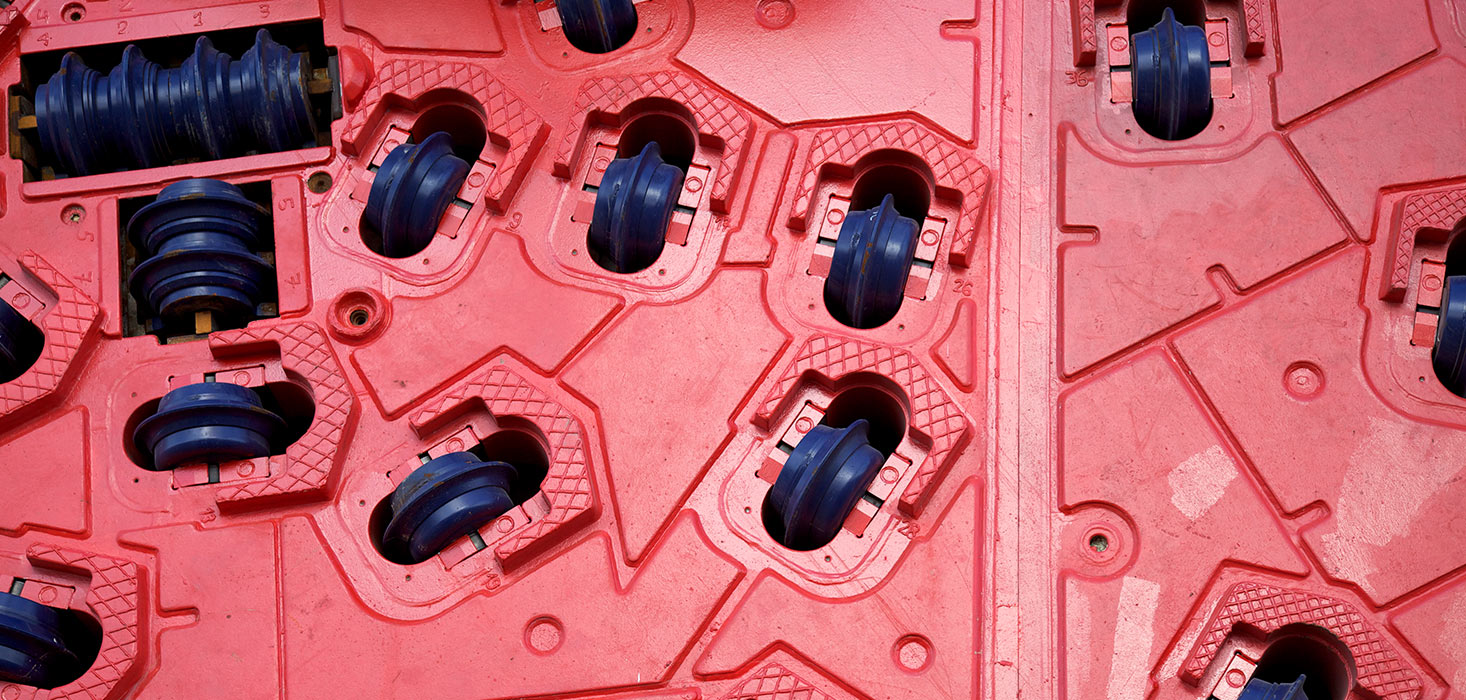

MICRO TUNNELING CASE STUDY

Digging Deep: Trinity Provides Custom Solution for a Tunneling Project

When it comes to temporary power solutions, equipment that meets a client’s exact specifications doesn’t always exist. When that happens, our experienced team of technicians and temporary power specialists can work with the client and any other stakeholders to modify existing equipment. The result, as it was for one recent client, is typically a purpose-designed solution that saves them the cost of renting less-than-ideal equipment.

The Client: An Established Tunneling Company

From their beginnings as a plumbing company in 1950, this client has grown into a North America-wide tunneling company. The services they offer now range from tunneling and microtunneling to foundation work, slip lining and open-cut construction. Their excellent reputation is built on consistently delivering high-quality, innovative solutions on time and on budget.

The Challenge: Mismatched Voltage for Tunneling Equipment

Our client was contracted to provide microtunneling services on a project in southwestern Ontario. They planned on using grid power to operate their tunneling machine. However, while their equipment ran at 480V, the utility power they had access to was 600V. They reached out to Trinity Power to help them source the best transformer for the job.

Our Solution: A Custom-Modified Transformer

Trinity supplied a 1000kVA 600V-480V Transformer with with a 1600A breaker disconnect to step the utility power down from 600V to 480V. Working with the utility company, the Trinity Team also added CT and PT compartments and a metering cabinet in order to meet the electrical utility’s requirements. We were also careful to ensure the modifications would meet our client’s needs.

The Result: The Right Solution Without the Hassle

Thanks to the Trinity team’s custom solution, not only did our client save time and money — they also saved the hassle of trying to source and build their own solution. And because we were able to work to their timeline, they were able to keep their project on schedule.

HIGH-QUALITY, SAFE & EASY-TO-USE

SEE OUR FLEET

Trinity Solution Powers a Remote Ontario Work Camp

Power and distribution for a work camp in Ontario.

A Quick Lead Time Leads Waste Company to Trinity Power

Our quick response helped this project stay on schedule.