- OUR APPROACH

-

COMMITTED TO YOUR SUCCESS

Our approach, developed over decades of experience, is fine-tuned to get the results you want.

We deliver concept-to-completion solutions, designed by temporary power specialists with access to the largest inventory of high-quality power generation and distribution equipment in North America.

-

- Equipment

-

RENTALS

From a wide range of diesel and natural gas generators to transformers, cable, light towers and more, our large rental fleet and extensive vendor network ensure we’ll have the temporary power equipment that your project requires — every time.

-

- Industries

-

INDUSTRIES WE SERVE

For nearly 20 years, we have been at work powering projects across Canada’s industrial sectors.

Select from this sampling of industries to learn how we can put our expertise to work for you.

VIEW ALL- Projects

- About

-

A PROUD HISTORY. A BRIGHT FUTURE.

From our inception in 1998, we have been building our team on a foundation of excellence. Our team members’ passion, expertise and commitment are what have allowed us to grow into a national company with projects across Canada.

Click on the links to learn more about our history, our team or our career opportunities.

- Blog

- Contact

-

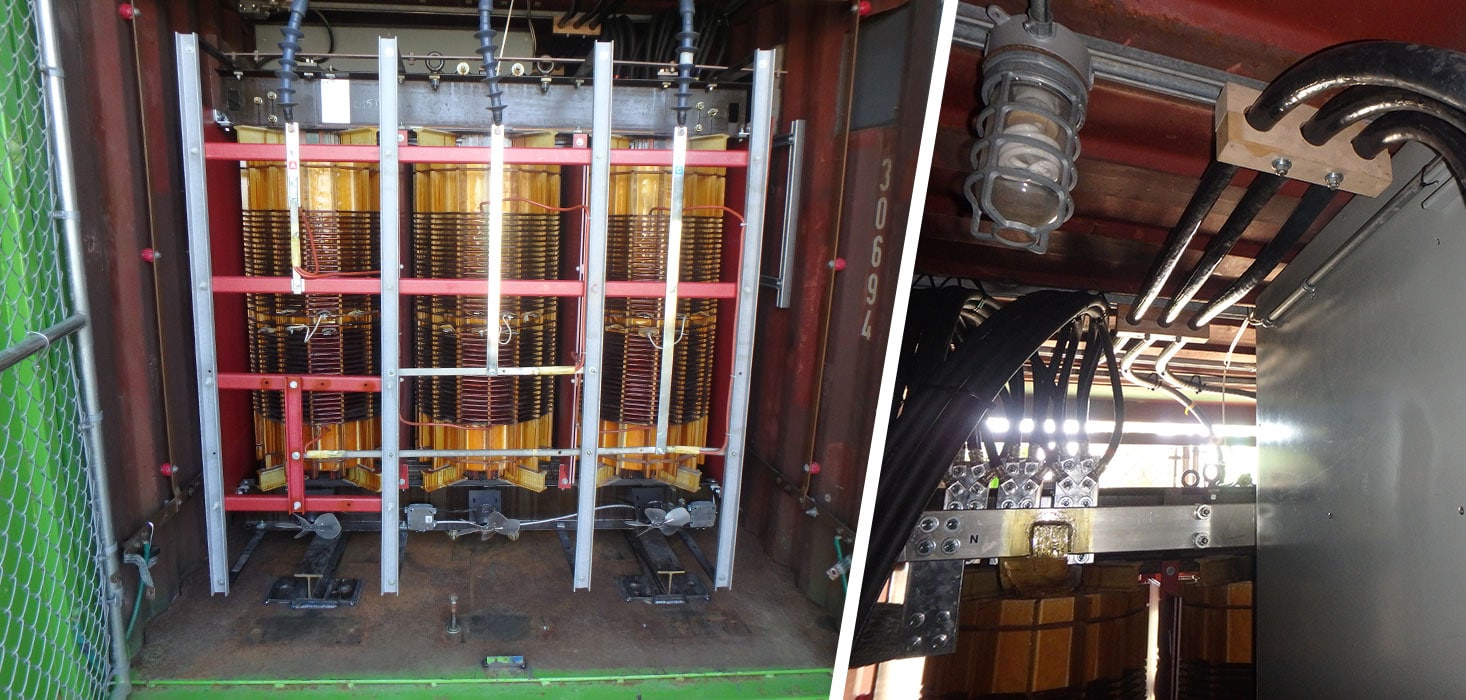

COMMERCIAL BUILDING CASE STUDY IN B.C.

Home Run Temporary Power Solution Saves Big on Fuel Costs

When it comes to sourcing equipment, the Trinity team rarely comes up empty-handed. Our extensive network of trusted vendors combined with our large in-house fleet of temporary power equipment usually ensures that we will be able to get what our clients need.

But every once in awhile, a piece of equipment is so uncommon, or in such high demand that sourcing it quickly gets tricky. So what does the Trinity team do when a project throws us a curve ball? Simple: we build a better bat.

The Client: A Leading Specialist in Electrical Power System Services

Providing specialized testing, maintenance, repair and inspection for critical electrical power systems, this BC-based client is a leader in their industry, as demonstrated by their many long-term clients.

With over 20 years in the business, their experience is hard to match, and their highly trained and certified technicians operate with the highest level of technical expertise.

The Challenge: A Failed Transformer and a Long Lead Time

When a failed transformer threw a wrench in operations at a commercial building, our client was brought in to help. In order to get things back up and running as quickly as possible, they had rented a 500kW 600V generator to handle the building’s critical loads until the transformer could be replaced.

The catch? The replacement transformer wasn’t due to arrive for another four months. Staring down the barrel of the steep fueling costs that would come with running a generator of that size for an extended period of time, our client was looking for a better alternative for their customer, and they came to Trinity Power.

Our Approach: A Custom-Made Solution With an Unusual Twist

With every passing minute burning more fuel — and more money, the Trinity team began the search for a 25kV 600V transformer that could stand in for the unit that was being replaced. In an unusual twist, we came up dry. Due to the size of the required transformer, a suitable option was simply unavailable locally.

The team needed to find a different solution, and quickly.

After surveying our existing fleet, we located a packaged substation that could do the job. There was just one small problem: the transformer core and coil needed replacement.

Doing what we do best, the Trinity team sourced replacement parts, and worked tirelessly throughout the weekend to bring the substation up to meet our quality assurance standards, so that we could deliver the 1500kVA 12.5kV-600V packaged substation our client needed according to their timeline.

We also provided perimeter fencing and a crane to help with the installation of this 25,000 pound piece of equipment.

The Result: A Significant Reduction in Fuel Costs and Environmental Impact

Thanks to our large fleet, technical expertise, and dedication to getting the job done, our client was able to offer their customer a solution that not only significantly reduced their projected fuel costs, but also mitigated the environmental impact of running a large generator for months at a time.

We’d say we hit it out of the park.

HIGH-QUALITY, SAFE & EASY-TO-USE

SEE OUR FLEET

Trinity Sources Hard-to-Find Load Bank on a Holiday Weekend

When a client needed a big load bank on short notice -- during a holiday -- the Trinity team delivered.

Trinity Saves the Day With Late-Night Power Restoration

Find out how we restored power to a multi-unit commercial building overnight.