- OUR APPROACH

-

COMMITTED TO YOUR SUCCESS

Our approach, developed over decades of experience, is fine-tuned to get the results you want.

We deliver concept-to-completion solutions, designed by temporary power specialists with access to the largest inventory of high-quality power generation and distribution equipment in North America.

-

- Equipment

-

RENTALS

From a wide range of diesel and natural gas generators to transformers, cable, light towers and more, our large rental fleet and extensive vendor network ensure we’ll have the temporary power equipment that your project requires — every time.

-

- Industries

-

INDUSTRIES WE SERVE

For nearly 20 years, we have been at work powering projects across Canada’s industrial sectors.

Select from this sampling of industries to learn how we can put our expertise to work for you.

VIEW ALL- Projects

- About

-

A PROUD HISTORY. A BRIGHT FUTURE.

From our inception in 1998, we have been building our team on a foundation of excellence. Our team members’ passion, expertise and commitment are what have allowed us to grow into a national company with projects across Canada.

Click on the links to learn more about our history, our team or our career opportunities.

- Blog

- Contact

-

Trinity Power Blog

We interview the experts to bring you unique perspectives on the news, technology and ideas that matter in your industry.How to Determine the Power & Size of Generator Needed Copy

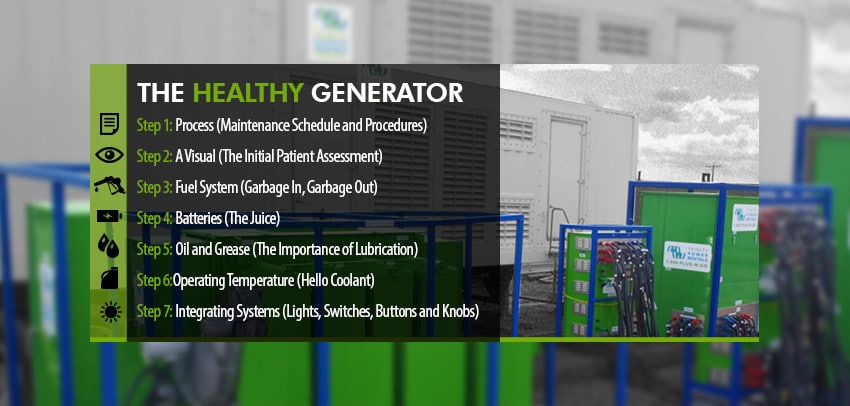

When assessing generator rentals, many business owners make the mistake of [...] Read MoreIntegrated Generator Systems – Lights, Switches, Buttons, Knobs

The integrated systems of a generator are very much like our brain Our [...] Read MoreGenerator Operating Temperature – Hello Coolant

The human integumentary system is the medium through which water evaporates to [...] Read MoreDiesel Generator Lubrication – Maintenance Tips

Much like another of our major internal organs, the oil pan functions in a [...] Read MoreGenerator Battery Maintenance – The Juice

The battery is the defibrillator of the electrical generating systems world The [...] Read MoreGenerator Fuel System – Garbage In Garbage Out

If the engine is the heart of the machine, then the fuel is its blood We use [...] Read MoreVisual Generator Inspection – The Initial Patient Assessment

We all hate the obvious The simple The easy The blatant answer that practically [...] Read MoreProcess – Generator Maintenance Schedule and Procedures

Why is a maintenance process so important Process is like a patient’s [...] Read MoreThe Healthy Generator – A Seven Part Series

In an ideal word, machines would never break down, construction problems would [...] Read MoreOptimizing Planned Mine Maintenance Downtime

According to the British Columbia Exploration and Mining Summary for 2013, the [...] Read MoreHow to Determine the Power & Size of Generator Needed

When assessing generator rentals, many business owners make the mistake of [...] Read MoreSubscribe for access to exclusive content