- OUR APPROACH

-

COMMITTED TO YOUR SUCCESS

Our approach, developed over decades of experience, is fine-tuned to get the results you want.

We deliver concept-to-completion solutions, designed by temporary power specialists with access to the largest inventory of high-quality power generation and distribution equipment in North America.

-

- Equipment

-

RENTALS

From a wide range of diesel and natural gas generators to transformers, cable, light towers and more, our large rental fleet and extensive vendor network ensure we’ll have the temporary power equipment that your project requires — every time.

-

- Industries

-

INDUSTRIES WE SERVE

For nearly 20 years, we have been at work powering projects across Canada’s industrial sectors.

Select from this sampling of industries to learn how we can put our expertise to work for you.

VIEW ALL- Projects

- About

-

A PROUD HISTORY. A BRIGHT FUTURE.

From our inception in 1998, we have been building our team on a foundation of excellence. Our team members’ passion, expertise and commitment are what have allowed us to grow into a national company with projects across Canada.

Click on the links to learn more about our history, our team or our career opportunities.

- Blog

- Contact

-

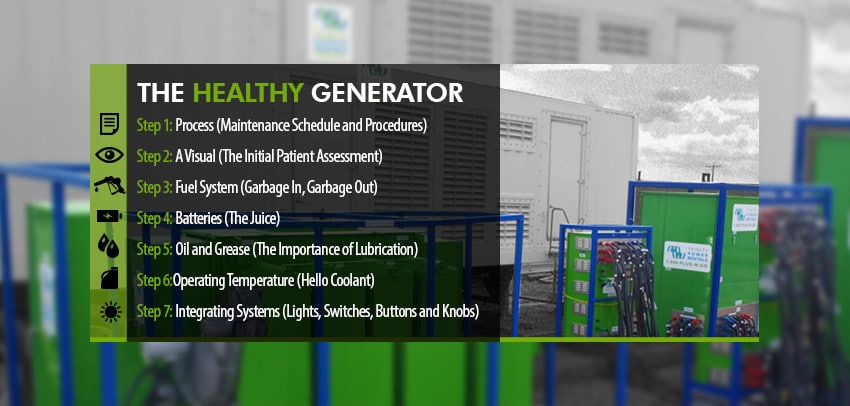

Why is a maintenance process so important?

Process is like a patient’s annual physical exam. The right process, like that annual exam, can be crucial in preventing a generator set from ever getting sick.

Following an established process can help protect a genset from otherwise inconsistent human behavior. As experienced as we might be, we are not always consistent in applying that experience in the field. Having a sound maintenance process is the best way to eliminate problems before they happen, and it can aid in the diagnosis of a small problem before it becomes a much larger one. Machines that can supply up to 2 megawatts of power require this kind of consistent service, especially when hundreds – or even thousands – of workers might be dependent on their output. So, what goes into that process?

Log Book (aka, The Chart)

The Log Book should contain detailed information regarding what regular maintenance procedures have been performed, when and by whom. A Log Book is neither a punch card nor a means of personnel evaluation. Instead, like a doctor’s chart, it’s a repository of data maintained throughout the course of a genset’s life and function.

And, like a chart, the Log Book should also be particular to the machine. Size and application have much to say about the nature of maintenance. Load size and fluctuation can greatly influence generator performance, along with a range of application-specific details, including: geography, latitude, altitude weather and temperature. All of these factors play important roles in the type and frequency of maintenance practices. Including this very critical information will aid the team of technicians whose job it is to ensure the smooth performance of the machine.

This information should be included along with the physical maintenance procedures performed on a regular basis. What regular maintenance procedures? Below is a guide, in chart form, detailing the most typical diesel maintenance schedule:

| Maintenance Items | Daily | Weekly | Monthly | Every 6 Months | Yearly | Exceptional Circumstances* (Cold Weather,Altitude,Etc.) |

|---|---|---|---|---|---|---|

| Visual Inspection | X | X | ||||

| Inspect Charge-Air Piping | X | |||||

| Inspect Engine Oil | X | |||||

| Inspect Coolant Level | X | |||||

| Inspect Fuel Level | X | X | ||||

| Inspect Coolant Heater | X | |||||

| Deplete Fuel Filter | X | X | ||||

| Test Battery Voltage and Charge Level | X | |||||

| Inspect Air Cleaner | X | X | ||||

| Deplete Water from Fuel Tank | X | X | ||||

| Inspect Coolant for Anti-Freeze Concentration | X | X | ||||

| Inspect Drive Belt Tension | X | X | ||||

| Deplete Exhaust Condensate | X | X | ||||

| Inspect Alternator | X | |||||

| Replace Fuel Filters | X | |||||

| Coolant Filter – Replace | X | |||||

| Clean Crankcase Breather | X | |||||

| Air Cleaner Element– Replace | X | |||||

| Inspect Radiator Hoses | X | X | ||||

| Replace Oil and Filter | X | X | ||||

| Cooling System – Drain and Clean | X | |||||

| * Exceptional circumstances indicate certain tasks may be performed more frequently than indicated. | ||||||

This is a general list. It doesn’t address all of the scenarios and situations in which a genset might be in service. Every machine and application is different but the process, once established, should remain consistent.

In subsequent articles we’ll provide further details into some of the more crucial elements related to generator maintenance. In that first item we’ll explore what to look for on your visual inspection: The Initial Patient Assessment.

Related Articles

Subscribe for access to exclusive content