- OUR APPROACH

-

COMMITTED TO YOUR SUCCESS

Our approach, developed over decades of experience, is fine-tuned to get the results you want.

We deliver concept-to-completion solutions, designed by temporary power specialists with access to the largest inventory of high-quality power generation and distribution equipment in North America.

-

- Equipment

-

RENTALS

From a wide range of diesel and natural gas generators to transformers, cable, light towers and more, our large rental fleet and extensive vendor network ensure we’ll have the temporary power equipment that your project requires — every time.

-

- Industries

-

INDUSTRIES WE SERVE

For nearly 20 years, we have been at work powering projects across Canada’s industrial sectors.

Select from this sampling of industries to learn how we can put our expertise to work for you.

VIEW ALL- Projects

- About

-

A PROUD HISTORY. A BRIGHT FUTURE.

From our inception in 1998, we have been building our team on a foundation of excellence. Our team members’ passion, expertise and commitment are what have allowed us to grow into a national company with projects across Canada.

Click on the links to learn more about our history, our team or our career opportunities.

- Blog

- Contact

-

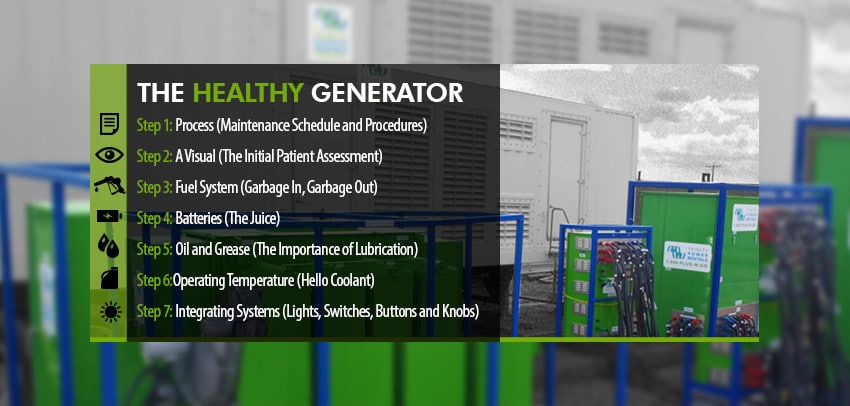

Integrated Generator Systems – Lights, Switches, Buttons, Knobs

Dec 08, 2014

The integrated systems of a generator are very much like our brain. Our consciousness is only a small representation of all that our brain controls. Much of the real work is performed on the unconscious level. Heart rate, internal temperature, hormone regulation, and circadian rhythm all happen without us knowing. The integrated systems of a generator can be given this same label. They’re necessary for the overall function of the generator and are designed to occur independent of exterior input.

But hold on. Don’t get carried away. Though these various functions of the machine happen without exterior input they are not without maintenance. After all, a gauge is only as good as the accuracy of the information it provides. A good operator will not rely solely on one measure as the authoritative answer as to what may or may not ail a machine.

To start, what are the various indicators and what do they tell us?

Essentially you can divide the generator in half: One half being the engine (which has already been discussed at length) and the other being the alternator that gives us the electrical energy.

The gauges on the machine tell us the mechanical function of the engine – things like oil pressure, coolant temperature, fuel level, battery voltage, and engine revolutions per minute. Those functions are like the base line testing of a patient, and any change from their normal operating zone tells us that not all is well and further deductive work is necessary to identify any problems.

The alternator half of the generator includes the output (voltage, current and frequency) and the optimization of the integrated systems. (For instance, the control panel is powered by, and has dominion over, the battery and charger by providing a float charge. It tells us how much of the battery is being extinguished to ensure its longevity.) The metering device for that output is contained in the control panel.

In addition to output, the machine also employs sensors to measure everything from heat, to moisture both inside and outside the machine. Those sensors are connected to the microprocessor in the control panel.

Some of the areas you may want to adjust include the way the operator interacts with the control panel, how the unit comes online and what information is displayed from the sensors.

Next to the LCD display screen will be a shut off or turn key that allows the operator to override the main system, go into a program and make alterations – all based on the system application where specific needs can be obtained.

Given the size and scope of most large scale gensets, it’s imperative that this sensitive equipment be protected against the elements, weather and corrosion. To this end, most control panels are equipped with membrane switches and keypads that are both temperature and waterproof.

The most important thing to remember about generator maintenance is even though the modern generator is equipped with the latest sensor equipment and information, there is no substitute for hands-on knowledge and training. A machine will only perform as well as it is maintained. The gauges and indicators are just that, measuring mediums to provide the operator accurate information on the machine’s performance. This series on maintenance practices is meant as a guide to help you better understand the processes and procedures that can help you get the most out of your machine.

Related Articles

Subscribe for access to exclusive content