- OUR APPROACH

-

COMMITTED TO YOUR SUCCESS

Our approach, developed over decades of experience, is fine-tuned to get the results you want.

We deliver concept-to-completion solutions, designed by temporary power specialists with access to the largest inventory of high-quality power generation and distribution equipment in North America.

-

- Equipment

-

RENTALS

From a wide range of diesel and natural gas generators to transformers, cable, light towers and more, our large rental fleet and extensive vendor network ensure we’ll have the temporary power equipment that your project requires — every time.

-

- Industries

-

INDUSTRIES WE SERVE

For nearly 20 years, we have been at work powering projects across Canada’s industrial sectors.

Select from this sampling of industries to learn how we can put our expertise to work for you.

VIEW ALL- Projects

- About

-

A PROUD HISTORY. A BRIGHT FUTURE.

From our inception in 1998, we have been building our team on a foundation of excellence. Our team members’ passion, expertise and commitment are what have allowed us to grow into a national company with projects across Canada.

Click on the links to learn more about our history, our team or our career opportunities.

- Blog

- Contact

-

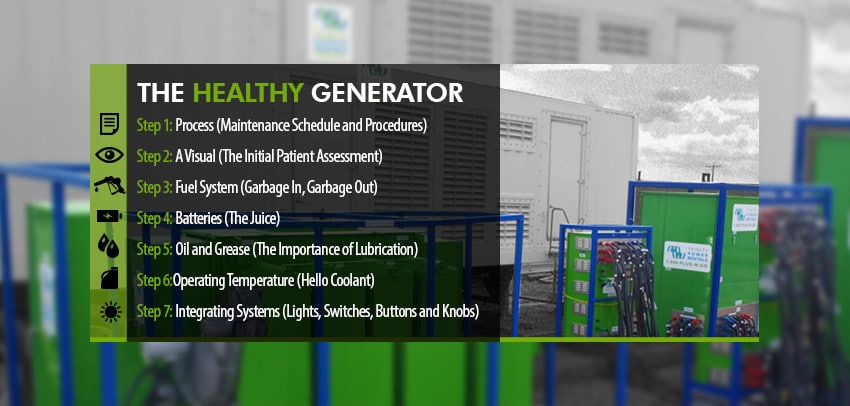

If the engine is the heart of the machine, then the fuel is its blood. We use this analogy because when fuel problems exist, the engine will eventually start to sputter. Garbage In equals Garbage Out.

Technically speaking, in such situations, combustion isn’t complete, or, at least, as ideal and total as it needs to be. As a result, unburned diesel will accumulate in the combustion chamber. An engine can only run as cleanly and efficiently as the quality of fuel allows.

What are the two most common fuel system problems? Water and Fuel degradation. Why is water such an issue? When water is stored in a tank, small microbes can and do dine on fuel. Water acts as the metabolizing agent. The food is the organic matter contained in the diesel. The waste caused by that consumption is hydrogen sulfide. Left untreated, hydrogen sulfide will form into a black slime that impedes combustion.

When optimal combustion hasn’t been achieved, the unburned portions of the fuel will accumulate where they can. If you’re lucky those particles will attach themselves to the cylinder wall. Together with the engine oil, they’ll migrate south into the oil pan, mitigating damage to the combustion chamber. But the chances are good that those teeny tiny particles will begin to accumulate where they’re least wanted, in the injectors. After a period of time of poor combustion, the injectors will eventually start to clog, and the generator engine will show outward signs that all is not well within. (Think shortness of breath, some chest pain, sweating.) The exhaust will change from white to a hazy blue to black soot.

Degradation

Diesel contains a heavy constituent of crude oil called asphalts. In nominal conditions, those asphalts are in solution and burn along with the other components. If, however, the diesel has been sitting, those heavier constituents can break apart. Like materials will attract one another and accumulate in the fuel. With enough weight, they’ll sink, and coat the bottom of the tank like roofing tar. The compromised fuel result is shorter cycles and incomplete combustion times. But, like a clever physician the generator operator has a few tricks up his/her sleeve to detect this issue in its infancy.

Fuel filter replacement

With or without problems, the fuel filter of a generator should be changed after approximately 300 hours of operation (more frequently in extreme heat or cold). This is typically the threshold of acceptable performance.

Fuel filter inspection. The filter offers a blood sample of all that’s circulating (or not) within the combustion chamber. If performance has been suffering and improves with the change then there is potential for a fuel problem. And if the outside of the filter media shows signs of a slimy dark material then microbes have invaded your fuel source.

Prevention: Keep the water out

Water most commonly begins to reveal itself when the seasons change, particularly when summer gives way to winter. This is when you need to keep the tank full. Any exposed surface area, like the inside of a tank, can produce condensation naturally. The key is to minimize the exposure.

Test the tank. Because water is heavier than oil, if it’s present it will settle at the bottom of the tank. Take a long, ½-inch PVC pipe, attach Water Cut Paste to the end and dip it to the bottom of the tank. Wait a few minutes before extracting. The paste will change colour if it’s been exposed to water.

Like our own most important organ, the heart, an engine can still perform under less than ideal conditions. However, to achieve optimal combustion and an extended, life a healthy generator needs high-quality fuel.

In the next post we’ll delve into the juice behind the engine: Generator Battery Maintenance – The Juice

Related Articles

Subscribe for access to exclusive content